By Abby Feinstein on December 16, 2022

Time is money, but perhaps nowhere more so than in the commercial roofing trade. Long before COVID-19 and social distancing guidelines added a new layer of complexity to most construction projects, the industry was facing skilled labor shortage stemming from the 2008 recession.

In commercial roofing — where experience is required to complete jobs in a way that is timely and cost-effective – roofing contractors are expected to deliver quality, watertight low-slope roof systems while still turning a profit. With limited labor resources and leaner operations, however, contractors can’t just rely on the efficiency of the products they use – they must also manage their crews with increasing efficiency and ingenuity to remain solvent. That includes predicting labor costs and finding ways to intelligently cut costs.

Importance of correctly predicting labor costs on estimates

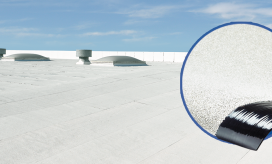

To address the construction labor shortage and other pressures facing contractors, CertainTeed developed its Flintlastic® SA product line of self-adhering polymer-modified bitumen roof membranes. These products require less skill, time and effort to install than traditional bituminous products, which require torched application, hot-mopped membranes, or membranes set in cold adhesive. The profit margin commercial contractors can extract from a job, however, often has more to do with how predictably they can estimate the job and how efficiency their crews can do the job.

In an effort to objectively to quantify the labor-savings offered by self-adhering roof membranes, CertainTeed commissioned Trinity|ERD, a Seattle-based building envelope consulting firm, to conduct “Factors Impacting Low-Slope Roofing: A National Labor Study.” This independent, five-year project looked at the installation of 45 roof systems with six roof coverings in multiple configurations in five U.S. regions. The researchers isolated and timed product and task-level installation data and observed where efficiencies or inefficiencies occurred.

While the study came back with important information about how various low-slope roofing systems install, it also produced valuable insights about how contractors can do their jobs better in order to realize cost savings.

Tightly Managed Crews Lead to Greater Profit Margins 0

BY ABBY FEINSTEIN ON DECEMBER 16, 2022BUILDING FORWARD, BUSINESS TIPS, INSIDER LOOK, KEEP CRAFT ALIVE, TRADE TALK

Time is money, but perhaps nowhere more so than in the commercial roofing trade. Long before COVID-19 and social distancing guidelines added a new layer of complexity to most construction projects, the industry was facing skilled labor shortage stemming from the 2008 recession.

In commercial roofing — where experience is required to complete jobs in a way that is timely and cost-effective – roofing contractors are expected to deliver quality, watertight low-slope roof systems while still turning a profit. With limited labor resources and leaner operations, however, contractors can’t just rely on the efficiency of the products they use – they must also manage their crews with increasing efficiency and ingenuity to remain solvent. That includes predicting labor costs and finding ways to intelligently cut costs.

Importance of correctly predicting labor costs on estimates

To address the construction labor shortage and other pressures facing contractors, CertainTeed developed its Flintlastic® SA product line of self-adhering polymer-modified bitumen roof membranes. These products require less skill, time and effort to install than traditional bituminous products, which require torched application, hot-mopped membranes, or membranes set in cold adhesive. The profit margin commercial contractors can extract from a job, however, often has more to do with how predictably they can estimate the job and how efficiency their crews can do the job.

In an effort to objectively to quantify the labor-savings offered by self-adhering roof membranes, CertainTeed commissioned Trinity|ERD, a Seattle-based building envelope consulting firm, to conduct “Factors Impacting Low-Slope Roofing: A National Labor Study.” This independent, five-year project looked at the installation of 45 roof systems with six roof coverings in multiple configurations in five U.S. regions. The researchers isolated and timed product and task-level installation data and observed where efficiencies or inefficiencies occurred.

While the study came back with important information about how various low-slope roofing systems install, it also produced valuable insights about how contractors can do their jobs better in order to realize cost savings.

Insights on Crew Management from the Labor Study

- Contractors should make accommodations for environmental factors. Temperature and environment should always should be factored into project estimates. Cold weather often adds work in the form of heating adhesives, longer time periods for relaxing rolls, longer welding times of membranes, and (in the case of cold-weather clothing) decreased mobility. Heat often causes stress and fatigue, resulting in more rest and water breaks. Also, overnight projects are typically slower than daytime projects as work areas are constrained to lighted areas and tools are harder to locate.

- Coordinated staging and assignments makes jobs easier. Installation is easiest crews work as a coordinated team. Crew members are most productive when their individual work is narrowly defined as opposed to a range of tasks. For example, when handheld screw guns were used during the study, workers who staged and placed screws and plates as one phase of work and were followed by another crew member who installed them were more efficient than a single person carrying pouches of screws and plates. The rhythm of work is maintained when a worker focuses on a single task. Staging materials properly for installers ahead of time also makes projects move more quickly.

- Rooftop supervision and direction plays a key role in quicker installation times. Strong management and quality control pays dividends on the jobsite. This includes proper management of rooftop loading, break times, staging materials, prefabrication (such as combining screws and plates) and relaxing materials before installation. A lack of in-application quality control may save time and labor on the front end but typically requires a crew to go back and correct issues noted by inspectors. In-application quality control helps avoid the time and money wasted sending crews back to a job site to complete repairs.

- Efficient tool and accessories use has a measurable effect on installation times. For example, the observed installation of a bituminous cap membrane with a multitorch cart was completed 86 percent faster compared with using a handheld torch. Automated screw and plate installers offer a noticeable time advantage but require a knowledgeable mechanic or crew member with rooftop access to spare parts to avoid machine jams or malfunctions. Poorly maintained automatic welders with inconsistent power and/or damaged parts also can slow productivity and negatively affect application quality. Blowers used on roofs to clean surfaces and move large sections of membrane also increased productivity in multiple applications.

Good communication is essential to safety, but also to productivity. Texting or emailing crew members the night before so they know what tasks need to be performed the next day and having the right materials waiting for them keeps crews from standing around not knowing what they’re supposed to do that day. Keeping high standards and setting the example will help your crews run like clockwork and make commercial roofing projects easier, regardless of the materials used.

For additional insights, visit our Labor Study webpage.